The dynamic and ever-evolving construction industry places a premium on efficient supply chain management, especially for emerging firms within developing countries. These entities confront a spectrum of challenges, including the volatility of material costs, logistical intricacies, and the imperative for cost-effective solutions.

Mastery of supply chain strategies becomes not merely an operational necessity but a critical factor in ensuring project success and sustainability.

Understanding the Supply Chain in Construction

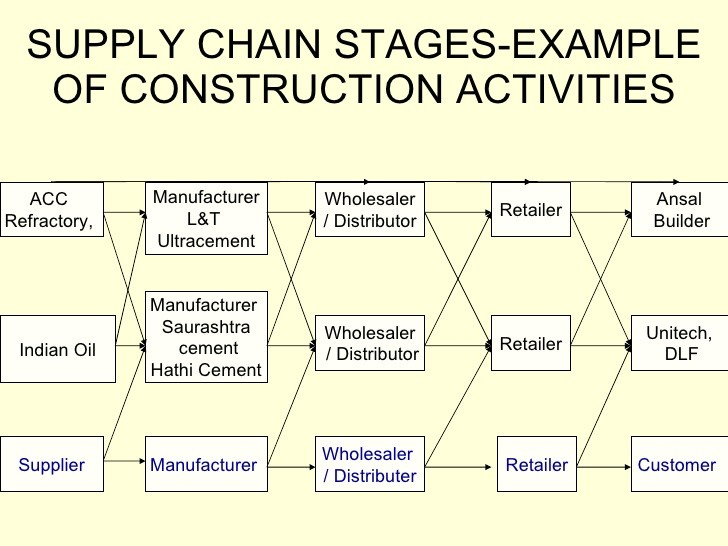

A supply chain encompasses all activities involved in the production and distribution of a company’s products, from sourcing raw materials to delivering the finished project to the client.

In construction, this translates to a complex network of suppliers, contractors, and service providers working in tandem to bring a project from blueprint to reality. A well-orchestrated supply chain is crucial for the seamless execution of construction projects. It involves meticulous planning and coordination in procurement, materials management, and logistics.

Construction supply chains are beset with challenges, including the variability of projects, the stringent regulations governing materials and building standards, and the pressing need to mitigate environmental impact. Thus, mastering supply chain management becomes a strategic imperative for construction firms aiming to thrive in competitive markets.

Key Strategies for Supply Chain Management

A well-orchestrated supply chain not only mitigates risks and reduces costs but also ensures projects are delivered on time and within budget. Below are elaborated strategies that can significantly bolster supply chain management:

1. Lean Management

The ethos of lean management is to deliver maximum value to clients while minimizing waste.

This translates to streamlining processes from material procurement to delivery on-site, ensuring that resources are utilized with utmost efficiency.

Implementing lean principles can help firms identify non-value-add activities and eliminate them, resulting in streamlined operations, reduced excess inventory, and significantly improved material flow efficiency.

The key is continuous improvement and flexibility, allowing firms to adapt quickly to changing project requirements and market conditions.

2. Just-in-Time Delivery

The Just-in-Time (JIT) strategy is predicated on reducing inventory holding costs and minimizing waste by ensuring materials and components are delivered precisely when needed. This approach demands meticulous planning and coordination with suppliers to align delivery schedules with the project’s timelines.

JIT can significantly reduce the need for large storage areas and minimize the risk of material damage or loss, thereby enhancing operational efficiency. However, its success hinges on reliable suppliers and an in-depth understanding of the construction project’s scope and timelines.

3. Strategic Sourcing

Strategic sourcing extends beyond mere price negotiation to foster long-term relationships with suppliers. It involves evaluating suppliers on various fronts such as reliability, quality, capacity, sustainability practices, and technological advancement. Selecting suppliers who align with the firm’s values and project requirements can ensure a steady supply of quality materials and equipment.

This approach not only guarantees cost-effectiveness but also enhances the reliability of the supply chain, providing a competitive edge in project execution.

4. Partnerships with Local Suppliers

Especially relevant for construction firms operating in developing countries, forming partnerships with local suppliers can offer several advantages. Local sourcing can significantly reduce transportation costs and lead times, offering more flexibility in supply chain management.

Moreover, it supports the local economy and can foster goodwill within the community. Working with local suppliers also allows for better agility in responding to unexpected changes or challenges, ensuring that project timelines are maintained.

Leveraging Technology for Efficient Supply Chain Operations

In an age where digital transformation is reshaping industries, the construction sector is no exception. The adoption of technology in supply chain operations presents an opportunity for emerging construction firms to achieve greater efficiency and transparency.

Inventory Management Software

Modern inventory management solutions offer powerful features for tracking and managing materials in real-time. These systems can automate ordering processes, predict inventory needs based on project timelines, and provide alerts on low stock levels. Adopting such technology, firms can ensure they have the right materials at the right time, reducing the risk of project delays.

Project Management Platforms

Comprehensive project management tools integrate various aspects of a construction project, from scheduling to communication and budgeting. These platforms can significantly enhance coordination between different stakeholders, ensuring that everyone is on the same page. Providing a centralized repository for project information can help avoid miscommunications and ensure timely decision-making.

Collaborative Platforms for Supplier Interaction

Technologies that facilitate direct communication and collaboration with suppliers can transform the supply chain landscape. Platforms that enable real-time updates, document sharing, and collaborative planning can strengthen relationships with suppliers and streamline procurement processes.

For emerging construction firms, integrating these technologies into their operations can cut waste, enhance communication, and improve overall supply chain coordination. The challenge lies in selecting the right technologies that align with the firm’s specific needs and ensuring the workforce is trained to leverage these tools effectively.

Building and Maintaining Supplier Relationships

The robustness of a firm’s supply chain often hinges on the strength of its relationships with suppliers. These alliances are pivotal for the uninterrupted provision of materials and services that meet both quality and cost objectives.

To foster and maintain these vital connections, emerging construction firms should employ several strategic practices:

Regular Communication

Consistent and open dialogue with suppliers helps to build a foundation of trust and mutual understanding. It ensures that both parties are aligned on expectations, project timelines, and quality standards. Regular check-ins can also provide early warnings of potential disruptions, allowing for proactive adjustments to plans.

Fair and Transparent Contract Terms

Contracts that are clear, fair, and beneficial to both parties lay the groundwork for long-term relationships. These agreements should include transparent terms regarding pricing, delivery schedules, and dispute resolution mechanisms. Fair contracts not only secure a reliable supply chain but also encourage suppliers to invest in quality service delivery.

Collaborative Problem-Solving

Challenges and conflicts are inevitable in any business relationship. Approaching these situations with a mindset geared towards collaborative problem-solving can strengthen relationships. By working together to overcome obstacles, firms and their suppliers can develop solutions that are mutually beneficial, fostering a sense of partnership rather than mere transactional interaction.

Strategic Partnerships

Beyond transactional relationships, developing strategic partnerships with key suppliers can offer significant advantages. These deeper collaborations might involve joint efforts in innovation, shared investments in technology, or cooperative training programs. Such partnerships can lead to improvements in product quality, cost savings, and enhanced supply chain resilience.

Practical Considerations and Challenges

While the implementation of advanced supply chain strategies offers a clear path toward operational excellence, construction firms must contend with a variety of practical considerations and challenges:

Budget Constraints

Financial limitations often pose the most significant barrier to adopting new supply chain practices. Investment in technology, training, and developing new supplier relationships requires upfront costs that may not yield immediate returns. Careful financial planning and a focus on long-term benefits are essential for navigating these constraints.

Staff Training and Adoption of New Technologies

Introducing new technologies and methodologies necessitates a commitment to staff training and change management. Employees need to understand the value of new systems and how to effectively use them. Overcoming resistance to change requires demonstrating the practical benefits of these innovations and fostering a culture that embraces continuous improvement.

Adaptation to Local Market Conditions

For construction firms operating in diverse regions, especially in developing countries, strategies must be adapted to local market conditions. This could involve sourcing from local suppliers, complying with local regulations, and customizing supply chain practices to address specific logistical challenges.

Resistance to Change

Change is often met with resistance, whether from within the organization or from external partners. Overcoming this resistance requires clear communication of the benefits, involving key stakeholders in the planning process, and providing adequate support during the transition period.

Global Supply Chain Disruptions

In today’s interconnected world, events in one part of the globe can ripple through the supply chain, causing disruptions. Firms must develop contingency plans, such as diversifying their supplier base or stockpiling critical materials, to mitigate these risks.

Maintaining Flexible Operations

The ability to quickly adapt to changing circumstances is a hallmark of a resilient supply chain. This flexibility can be achieved through agile project management practices, versatile sourcing strategies, and a willingness to innovate in response to challenges.

Conclusion

Emerging construction firms, by integrating strategies such as lean management, just-in-time delivery, strategic sourcing, and technology adoption, position themselves to significantly boost operational efficiency and cut unnecessary costs. These practices not only aid in ensuring projects are completed on schedule but also enable firms to navigate the complexities of the industry with greater agility.

As the construction sector evolves, keeping pace with the latest in supply chain management innovations and adhering to industry best practices becomes crucial. Doing so ensures that firms remain competitive, ready to meet the challenges and capitalize on the opportunities of an ever-changing marketplace.